ESSO-M-2 controls vacancy/occupancy or tracks and operates as alternative to track circuits. ESSO-M-2 is easily integrated into any existing signalling systems during new construction, modernization or capital improvements. ESSO-M-2 controls track circuits of any length and configuration.

ESSO-M-2 Axle Counting System

- Tasks

- Advantages

- Areas of use

- Data Sheet

- Video about ESSO-M and ESSO-M-2 Systems

- Set of Equipment

- Technical Data

- Diagnostics

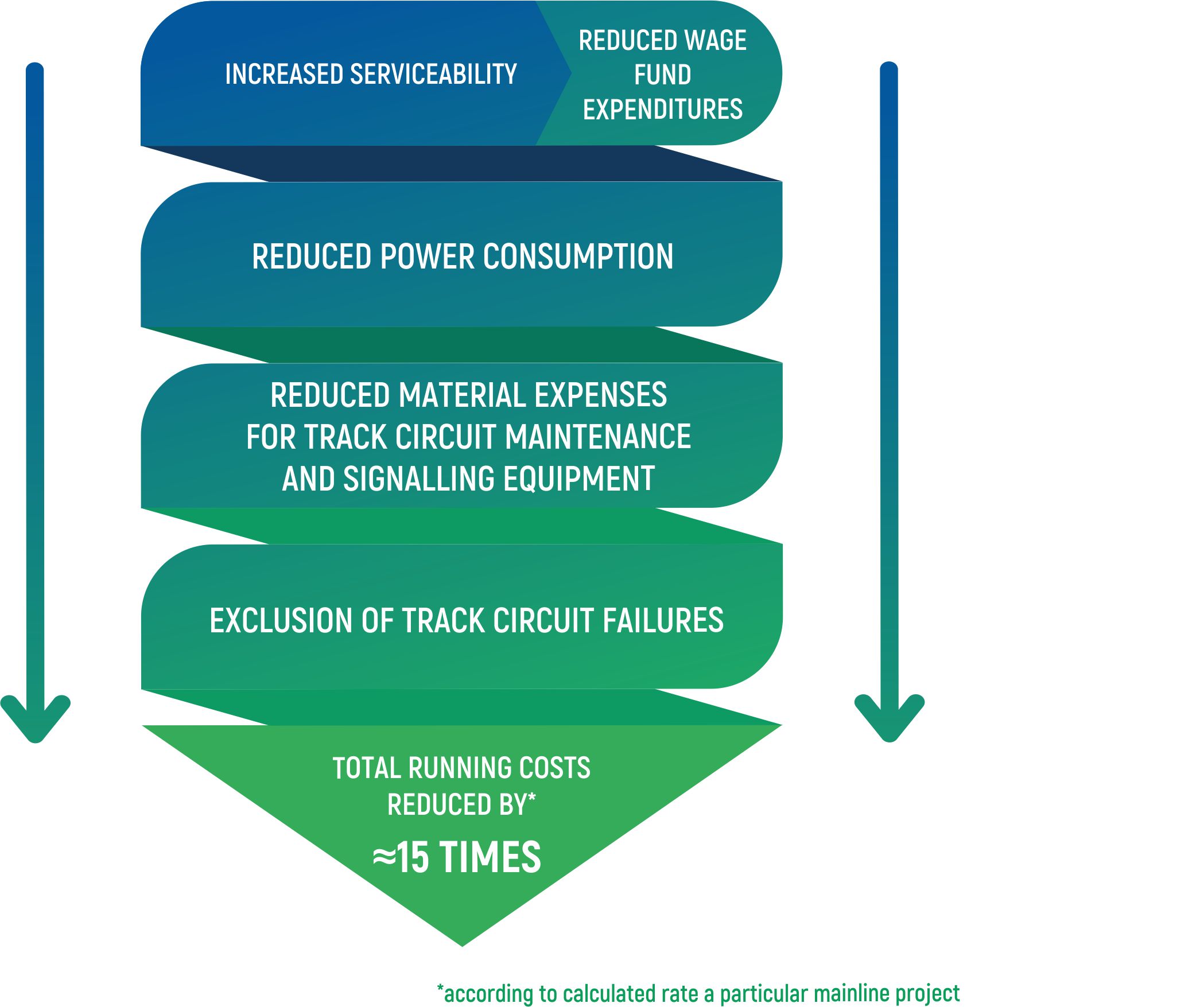

- Cost Efficiency

- Geography

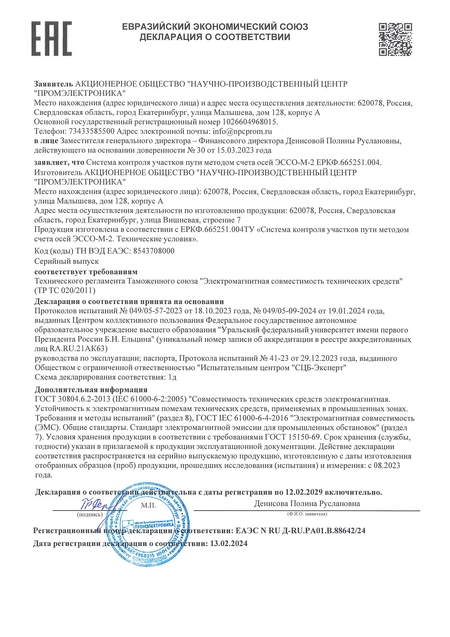

- Licenses and certificate

- Technical support

ESSO-M-2 Axle Counting System

Application

- Increases safety and operability level of train traffic control systems due to high RAMS values.

- Transmits data on train movement to upper level systems.

- Reduces running costs due to no external relays.

Advantages

- Operates with any type of roadbed resistance.

- Does not require electrical adjustments.

- User-friendly interface.

- Interactive troubleshooting guide.

- Embedded diagnostics, monitoring and event logging.

Railway Segments

- Train Traffic Safety Systems.

- Monitoring and Measuring Systems.

- Information and Logistic Systems.

- Wheel Location Systems.

Data Sheet

Video about ESSO-M and ESSO-M-2 Systems

Set of Equipment

Indoor Units

- DKU/DKU-M/SKM Wheel Sensors with Sensor Clamps.

SKM Wheel Sensor is a functional alternative to DKU-M Wheel Sensor and has an improved construction. SKM Sensor processes data on vibration, speed, movement direction and wheel location. The Sensor has an advanced immunity to traction current noises, SKM Sensor is applied in various climatic conditions.

Indoor Units

- KBR Evaluator Unit, PLR Counting Board and PLI Communication Board.

- UPSP Axle Counter Adapter.

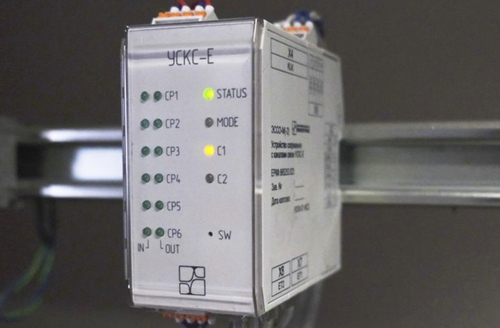

- USKS and USKS-E Interfacing Unit.

USKS-E Interfacing Unit ensures link with remote counting posts via redundant serial Ethernet Interface. Remote wheel sensors could be connected with ESSO-M and ESSO-M-2 systems.

- USSO Counting Posts Expansion Unit.

USSO allows enables ESSO-M and ESSO-M-2 systems to control switch sections of any size. In case of large switch sections the equipment cost is reduced for 15 %.

- PT Visual Panel.

- Overvoltage and Lightning Protection Devices.

- ESSO-M Diagnostic System.

Technical Data

- Supply voltage: 24 V DC, 220 V AC.

- Power consumption per one counting post: 2 W.

- Wheel speed: 0-360 km/h.

- Guaranteed data transmission distance between tpwer and trackside equipment: up to 5 km - via signal cable; up to 35 km - via communication cable; unlimited - via multiplexing equipment, radio relay and fiber-optic communication lines.

- One pair of wires for connection of counting post to tower units.

- Operating temperature range on outdoor units: -60°С to +70°С, indoor units: -40°С to +70°С.

- Electromagnetic compatibility and mechanical loads, climatic conditions: GOST 34012, EN 50125-3.

- Standard cabinet dimensions: 600х2100х720 mm.

- RS-485 (Modbus) Diagnostic Interface, Ethernet (ModBus TCP, SNMP).

- Main Interface: Serial Redundant Ethernet.

- Programmable Configuration.

- Can be integrated via relay-contact inteface.

- One Evaluator Unit controls 14 track sections.

- One cabinet houses 3 KBR Units: 42 track sections/68 counting posts.

Diagnostics and Monitoring

DS Diagnostic System comprised as software and hardware complex allows live tracking of system condition, transmits diagnostic information to upper level systems and log events. Information gathered by DS streamlines maintenance and troubleshooting as well as enables additional functions: tracking of a train movement along the station, maintenance of trackside equipment as per actual wear condition.

ESSO-M Work Station is designed for live monitoring of system status of the station, logging and viewing of information and troubleshooting. On booting ESSO-M Work Station displays the list of stations available for monitoring with their miniaturized layouts. Scale of the selected layout can be adjusted. Clicking on section displays detailed information on its status.

Cost Efficiency