MPC-I system performs interlocked control over trackside equipment: points, light signals, level-crossings and other signaling equipment.

MPC-I ensures all interlocking functions that are critical for safe train operation both on a station level and on a whole railway line. The interlocking system can be used on railway facilities of any configuration (small, medium and large stations, railway junctions, etc), which require routing of train and shunting traffic featuring light signal signaling, located at sections with automatic block systems, centralized traffic control.

MPC-I Computer Based Interlocking System

- Data Sheet

- Video

- Relay-Contact Interface

- ARM EC

- Digital Interface

- UKC Hot Standby

- Remote control, multistation mode

- MPC-I CAD Software

- SPPR

- Interfacing Unit

- Cost Efficiency

- Geography

- Licenses and certificate

- Reviews

- Technical support

MPC-I Computer Based Interlocking System

Data Sheet

Video about MPC-I Interlocking

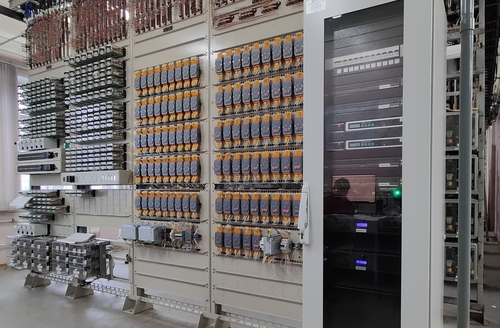

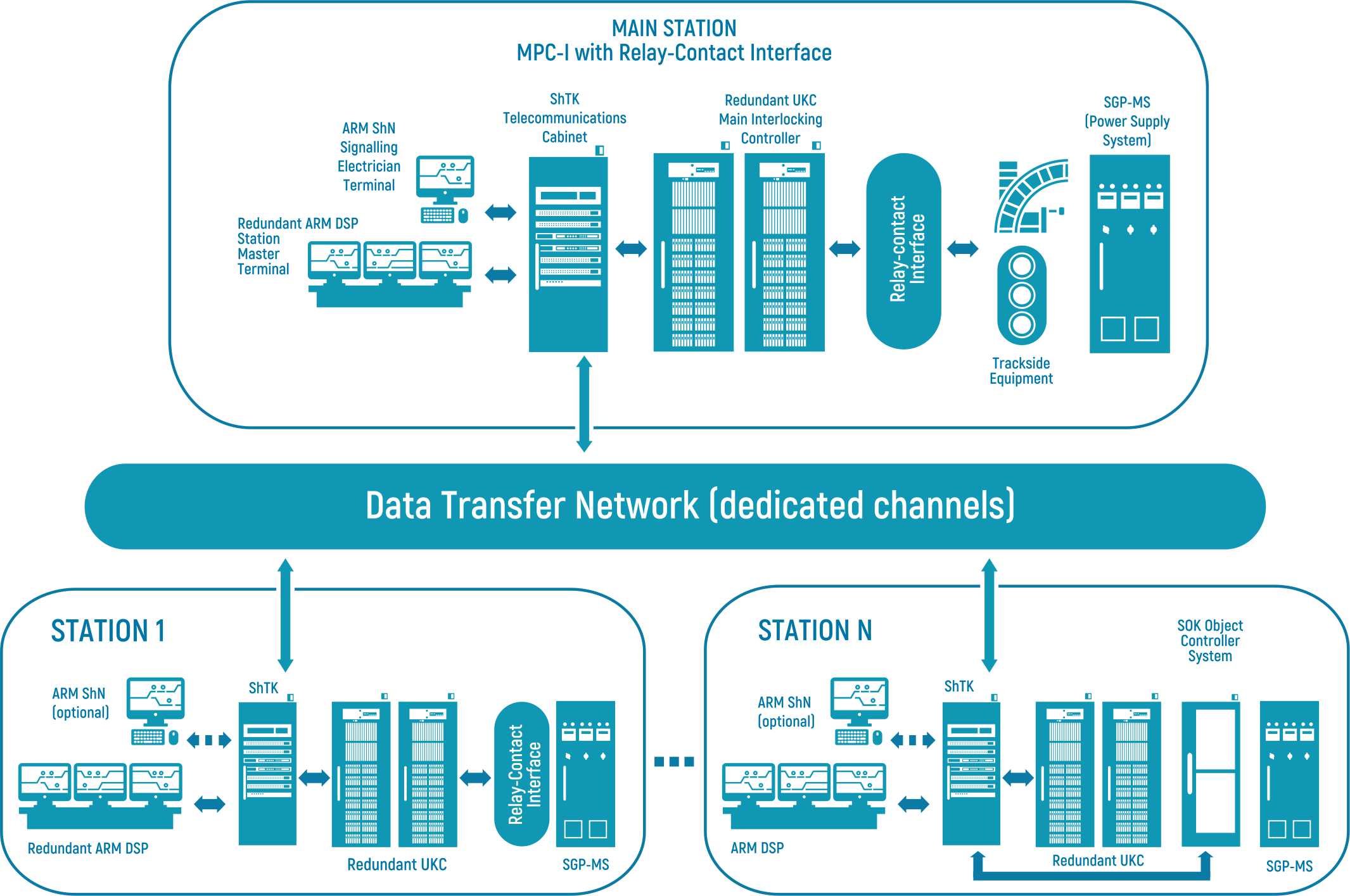

Relay-Contact Interface

MPC-I system with relay-contact interface uses railway and telemechanics relays of 1st reliability class. UKC interlocking controller cabinet with redundancy performs all logical dependencies of electronic interlocking. Expansion of controlled objects is achieved by increasing the number of UKC cabinets (up to 5 cabinets). This solution can be used on railway facilities of any configuration (small, medium and large stations, railway junctions, passing stations, railway posts, etc.) of mainlines and industrial railways.

Application

- Optimization of running costs due to system reliability and application of diagnostic systems.

- Increasing train traffic safety level.

- Replacement of outdated relay interlocking systems.

- Promoting better work ethics and productivity among operating personnel.

- Event logging, archiving and data base building of operating personnel actions and operation of station devices.

- Expansion of functional capabilities of interlocking systems.

- Saving usable area inside production premises of interlocking posts.

- Optimization of maintenance personnel numbers.

Advantages

- Capability to create information and control systems of any configuration and complexity.

- In-built event logging system with 100% redundancy.

- MPC-I employs all critical cybersecurity requirements.

- Main nodes of MPC-I are made of Russian-made components.

- In-built automatic subsystem based on KID family of devices for measurement of insulation resistances, voltages and currents at posts.

- System interface on 5 languages. Operating documentation on language of country of implementation.

- Highest safety integrity level SIL4 by CENELEC.

- Award by JSC Russian Railways for best quality of complex technical equipment.

- One of the most compact interlocking systems. Possible allocation in MKM equipment container.

Set of Equipment

- Redundant UKC Interlocking Controller Cabinet featuring software interlocking logic.

- ShTK Telecommunications Cabinet.

- Redundant ARM DSP Station Master (Operator) Terminal.

- Redundant ARM ShN Station Electrician Terminal.

- Interlocked objects (track circuit equipment, axle counting systems, light signals, point drives, shunting lights, vehicle inspection control panels and other trackside equipment produced by industrial manufacturers), signaling cable network, as well as object controllers and control relay circuits.

- SGP-MS Uninterruptable power supply system for computer-based systems.

Technical Data

- Average time to design logic (for station with 30 points): 1-2 weeks.

- Number of points per UKC Cabinet (one or first UKC): 35.

- Number of points per subsequent UKC Cabinet: 45.

- Total number of interlocked points per station: maximum 200.

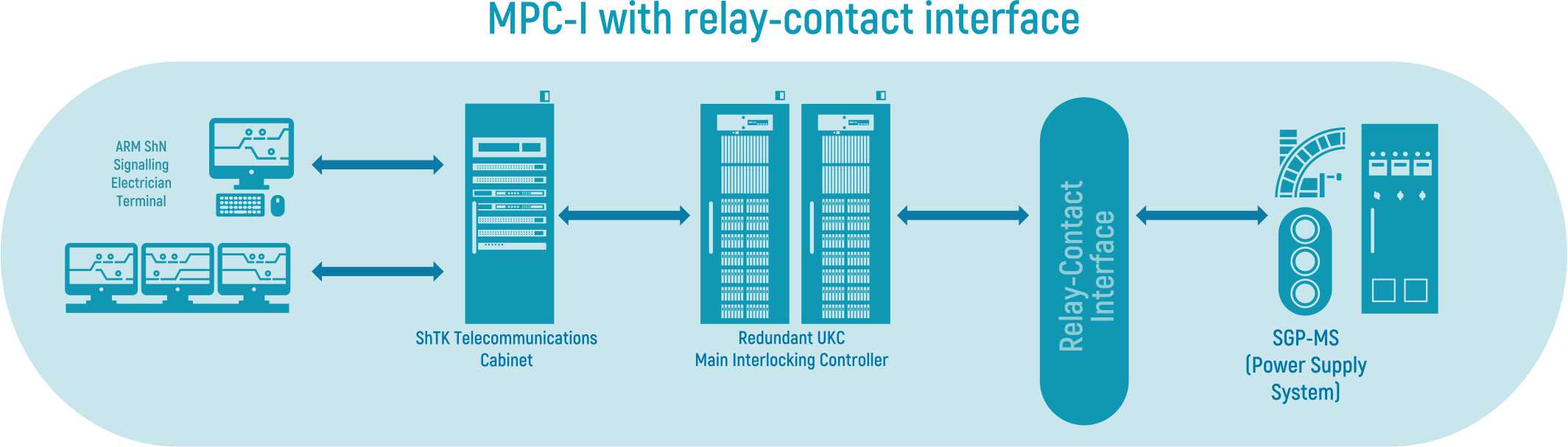

ARM EC

ARM EC – a solution for partial modernization of electric interlocking systems, in which a computing complex performs interlocking functions integrated with input/output controllers. Similar to relay-processor interlocking systems, applied software and hardware complex allows replacement of control panels of relay interlocking systems to modern ARM DSP terminals at minimum cost. Replacement of only control panel is also a viable option, leaving interlocking control circuit as it is.

ARM EC pieces together all advantages of classic interlocking systems and modern computer-based control systems, such as cost-efficiency, high reliability, simplicity of maintenance, convenient work places, capability to log events and view archive, remote station control, flexibility and promptness of correction of software project in case track layout of a station changes, etc.

This solution is applicable to existing stations of any size, when already installed electric relay interlocking systems have not depleted their operating resource yet or construction of new stations with a minor quantity of points.

Application

- Partial modernization of relay interlocking systems at minimal costs.

- Construction of new interlocking posts featuring control via ARM DSP Terminal.

- Organizing of remote control over already existing stations.

Advantages

- System is based on general industrial components.

- Creation of ARM EC software project is performed via MPC-I CAD via visual programming, oriented at users qualified as railway signaling engineers. Project development is identical to project development of interlocking systems. Project is created in the relay circuit editor. MPC-I CAD represents standard circuit nodes that perform interlocking functions, as standard units, which the user can allocate on a drawing and connect between each other in correspondence with geographical allocation of facilities on the station layout.

- Increased train traffic safety, throughput and capacity of a station, improved route building capability.

- Cost efficient solution, optimization of running costs for maintenance of relay equipment.

Set of Equipment

- Input-output controllers.

- Automated Station operator terminal and automated station electrician terminal as part of ARM EC.

- ShTK Telecommunications cabinet.

Technical Data

- Average time to design logic (at replacement of control panel only): 2-4 weeks.

- Average time to design logic (at replacement of control panel and interlocking group): 4-6 weeks.

- Interlocking system, which can be coupled with ARM EC – any existing interlocking system.

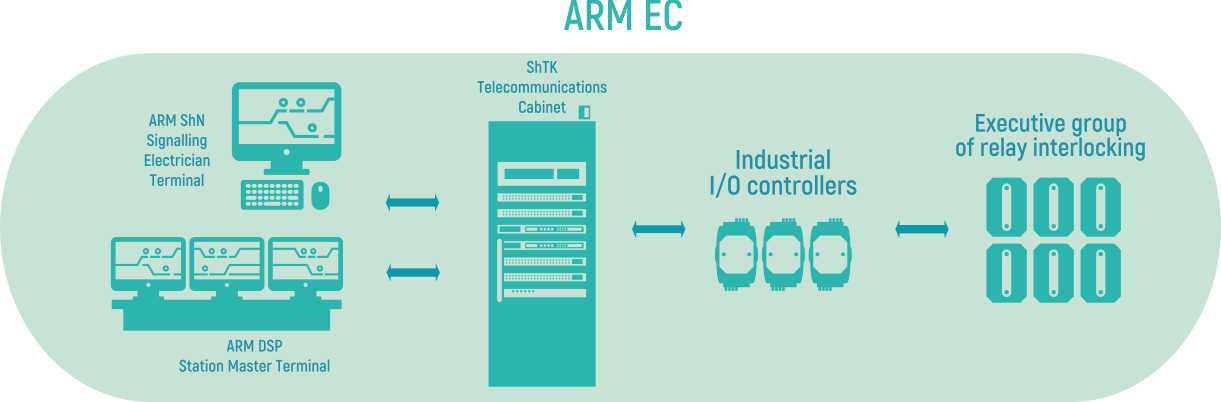

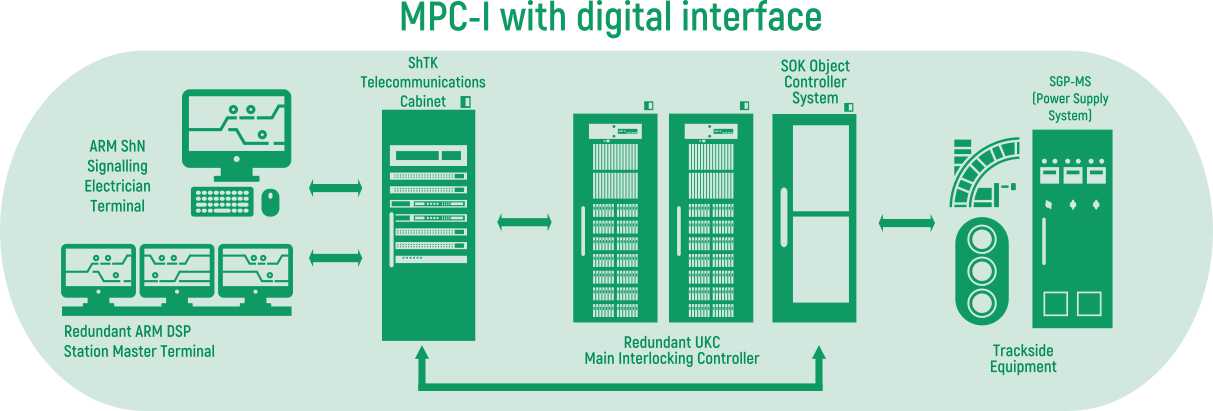

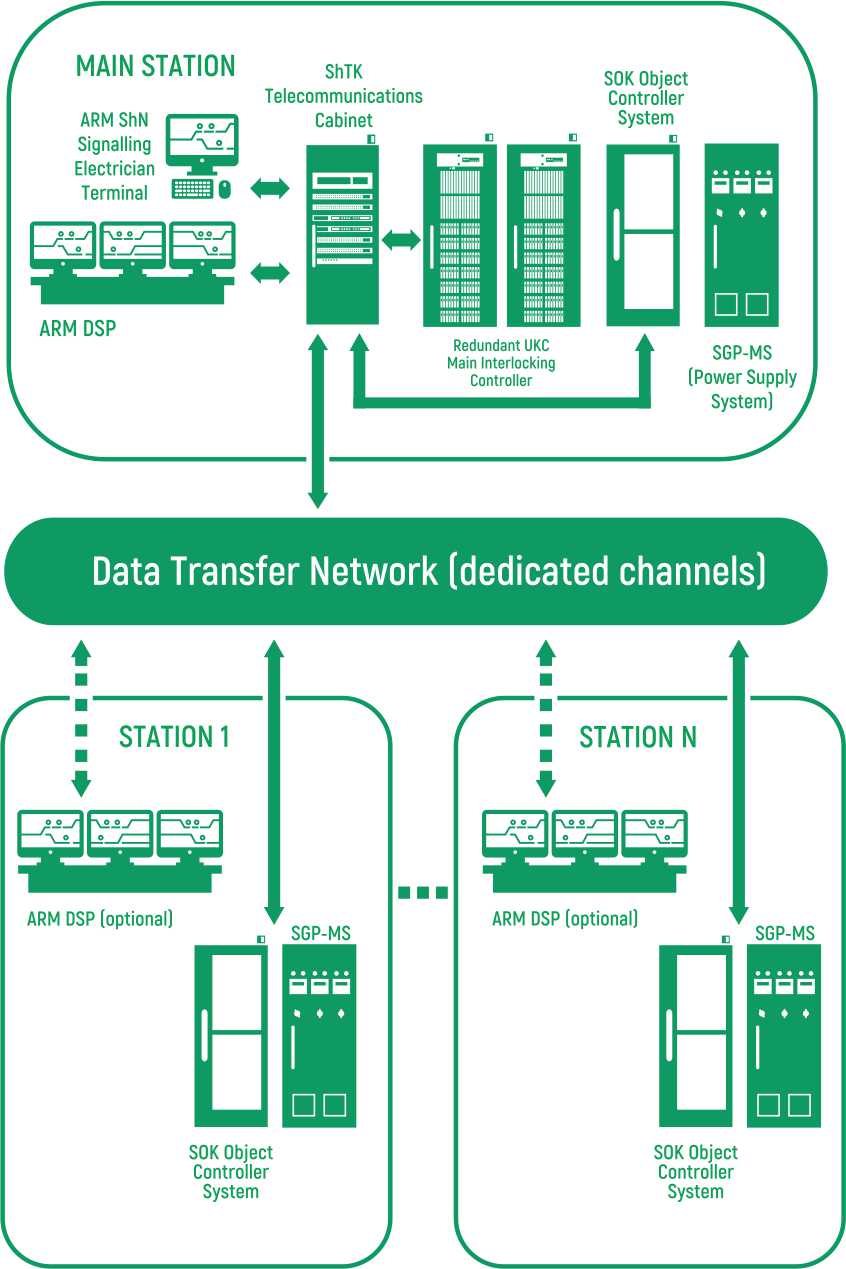

Digital Interface

MPC-I with digital interface for control over trackside objects (points and light signals) uses object controller system. It converts logical information exchanged with UKC controller, into physical information in correspondence with configuration of the interlocked station object. In case object controller system is used with MPC-I, one more redundant UKC cabinet is included into the system. Quantity of controlled objects is expanded by increasing the number of object controller cabinets.

Specialized communication object controllers carry out interaction of object controller system with UKC Cabinet via secure protocol. Point object controllers are designed for monitoring and control of point drives of direct current (110-230V), alternate single phase (220/230V), alternate triple phase (3x220 – 3x400V) current featuring two-/three-/four-/five-/seven-/nine-wire communication lines (nine-wire circuit is used for non-contact sensors).

Each light signal object controller capable of controlling 8 channels of light signal systems (distributed between 1-4 light signals) featuring monitoring of “filament” state (both in enabled and disabled state of a controlled object). Separate filaments of lamp light signals and LED-heads of standard light signals can be used as light signal systems.

Application

- Optimization of running costs due to reliability of the system and application of self-diagnostic systems.

- Increasing train traffic safety.

- Replacement of outdated relay interlocking systems.

- Promoting a better work ethics and productivity among operating personnel.

- Event logging, archiving and data base building of operating personnel actions and operation of station devices.

- Expansion of functional capabilities of interlocking systems.

- Saving usable area inside production premises of interlocking posts.

- Optimization of maintenance personnel numbers.

Advantages

- Decentralized equipment allocation on major stations, control of adjacent stations without organization of control posts (multistation control mode).

- Combining of relay interface with centralized control and modern non-relay centralized/decentralized interface of object controller system.

- Station control from joint posts without the necessity to install control equipment, complex power supply systems and other equipment on these stations.

- Multilevel diagnostic systems of MPC-I allows rapid search of pre-failure and failure states.

- Simple station modernization in case track layout changes.

- MPC-I employs all critical cybersecurity requirements.

- Main nodes of MPC-I are made of Russian-made components.

- In-built automatic subsystem based on KID family of devices for measurement of insulation resistances, voltages and currents at posts.

- System interface on 5 languages. Operating documentation on language of country of implementation.

- Highest safety integrity level SIL4 by CENELEC.

- Award by JSC Russian Railways for best quality of complex technical equipment.

- One of the most compact interlocking systems. Possible allocation in MKM equipment container.

Set of Equipment

- Redundant UKC Interlocking Controller Cabinet featuring software interlocking logic.

- ShTK Telecommunication Cabinet.

- SOK Object Controller System.

- Redundant ARM DSP Station Master Terminal.

- Redundant ARM ShN Station Electrician Terminal.

- Interlocked objects (track circuit equipment, axle counting systems, light signals, point drives, shunting lights, vehicle inspection control panels and other trackside equipment produced by industrial manufacturers), signaling cable network, as well as object controllers and control relay circuits.

- SGP-MS Uninterruptable power supply system for computer-based systems.

Technical Data

- Average time to design logic (for a station with 30 points): 1-2 weeks.

- Number of controlled objects per one object controller cabinet: points – up to 18 single point, up to 36 double points, light signals – up to 144 lights, including filament redundancy.

- Total number of interlocked points: unlimited.

- Nominal power supply voltage: 24 V DC (main + backup).

- Input voltage range: from 18 to 30 V.

- Operating temperature range: if allocated in permanent buildings and transportable modules: from -5°С up to +50°С; if allocated in thermo cabinets: from -60°С up to +85°С.

- Object controller cabinet dimensions (HxWxD): 600x2160x600.

UKC Hot Standby

Hot standby is used for increasing reliability of UKC operation and is based on “two out of two + two out of two” principle. Each UKC implements diagnostics of degradation level, which uses current or newly input diagnostic information to determine presence of failures and/or errors of interlocking controller hardware and integrated subsystems.

Each running cycle information on interlocking controller degradation level is transferred to the paired controller via cross communication channels.

Only one UKC with the lowest degradation level is working at a time, being an “active” set. Deactivated UKC, being “passive” has no effect on operation of the system.

Activation or deactivation of sets is based on the following data:

- In case degradation level of an active UKc is higher than that of a passive UKC for two or more hot standby cycles;

- An operator issued a command for manual UKC activation (using ARM DSP or ARM ShN). UKC swapping time does not exceed 200-500 ms.

Swapping between active and passive UKC sets does not interfere with technological process of a station.

Remote control, multistation mode

Remote control from a single post is used in low-traffic section to optimize the numbers of operating personnel, as well as on sections that require seasonal work of a station master on separate stations. Each station is fitted with MPC-I equipment set both with relay and non-relay interface.

- division of large-scale stations on unlimited number of zones for control (secular and seasonal);

- selection of sections for temporary local control (both with arrangement of additional working place and with control from point tower) on the station with shunting works;

- integration of low-density stations into joint control tower without using facilities of CTC tower and without installation of linear CTC post. Herewith, possibility of local control and monitoring still remains;

- arrangement of multi-level hierarchical control systems as zone-station-section-railroad with possibility of prompt transmission of control to the relevant level if necessary.

Multistation mode allows decentralized equipment allocation on large stations, control adjacent stations without organizing control posts on them.

In multistation mode only one MPC-I central processor (redundant UKC with ShTK), located on principal (sectional, zonal or major intermediary) station simultaneously interacts with object controllers of several adjacent railway junctions, passings and minor intermediary stations, premised on criteria of full CPU load.

Multistation mode allows for significant reduction of costs for comprehensive fitting of a railway section.

MPC-I CAD Software

MPC-I CAD computer-aided designing system is created to assist designers and customers of MPC-I system.

Thanks to CAD, the labor intensity of designing is significantly reduced, and the customer’s personnel with appropriate authorization can independently and promptly make corrections into MPC-I software in case track layout of a station changes. Moreover, CAD software helps reducing influence of the human factor.

Operating organizations are offered to variants for system reconfiguration – using design capabilities of JSC R&D Company Promelectronica or independent adaptaion within the changed part of the existing design with the help of MPC-I CAD and in cooperation with the Service Center of R&D Company Promelectronica.

SPPR Decision-making Aid System

SPPR Decisionmaking Aid System is an informational system that provides station master with additional information on current state of signaling equipment, errors in their operation, procedures during emergencies and other possible situations. Decisionmaking Aid System decreases the influence of the human factor on MPC-I operation and possible operation errors both under normal conditions and under conditions of device malfunction.

The system automatically detects:

- loss of point position control;

- tripping of train derailment detection system;

- tripping of fire alarm system;

- cyber security breach event, etc.

SPPR Decisionmaking Aid System can be integrated with MPC-I. SPPR provides recommendations on further actions in the form of a checklist with a capability of marking the fulfillment. Information from the system is displayed on an additional touch screen monitor.

- The following documents were used during development of SSPR System:

“Rules for technical operation of railways in the Russian Federation”, approved by order of the Ministry of Transportation of Russia of 23 June 2022 No.250 (hereinafter PTE), including “Instruction for signaling on railway transport of the Russian Federation” (Annex 1 to PTE) and “Instruction for organization of train traffic and shunting operations on railway transport of the Russian Federation” (Annex 2 to PTE). - Instruction for ensuring train traffic safety during operation of signaling devices and system TsSh-530-1, approved by decision of JSC Russian Railways No.2055r.

- Instruction “On operation of signaling equipment on stations”.

- Technical and executive directive of the station.

USKS-M Interfacing Unit

USKS-M Interfacing Unit is intended to connect axle counters directly with MPC-I Interlocking using vital serial data channels. It excludes auxiliary indoor axle counting units. Data is sent by Ethernet.

USKS-M is compatible with relay-contact MPC-I Interlocking and digital MPC-I Interlocking.

USKS-M is used along with MPC-I Interlocking on station and haul sections of public and non-public railways, metro and light rail transport.

Application of USKS-M reduces two times cost of indoor equipment comparing with ESSO-M-2 installation.

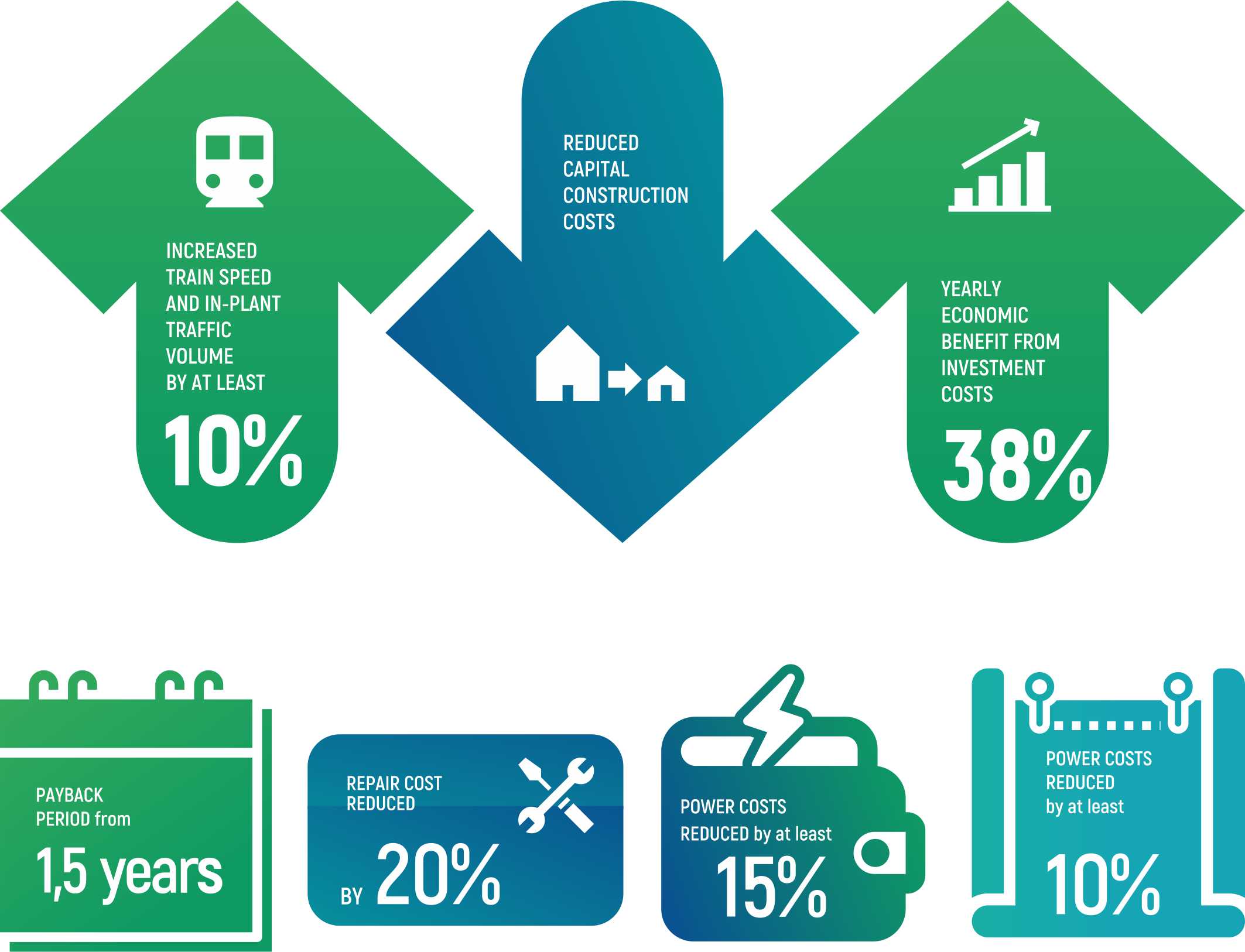

Cost Efficiency

Geography of implementation of the MPC-I system

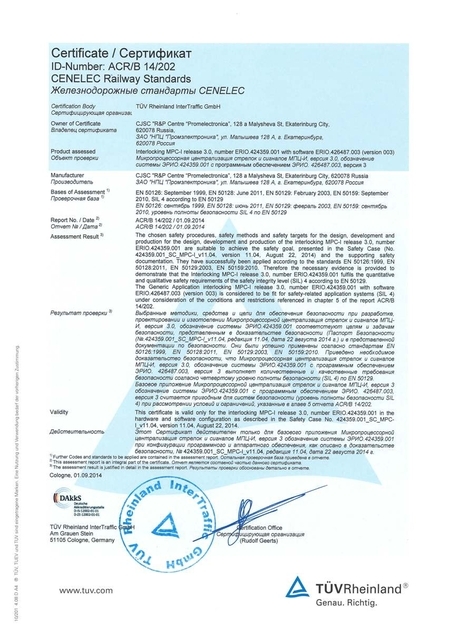

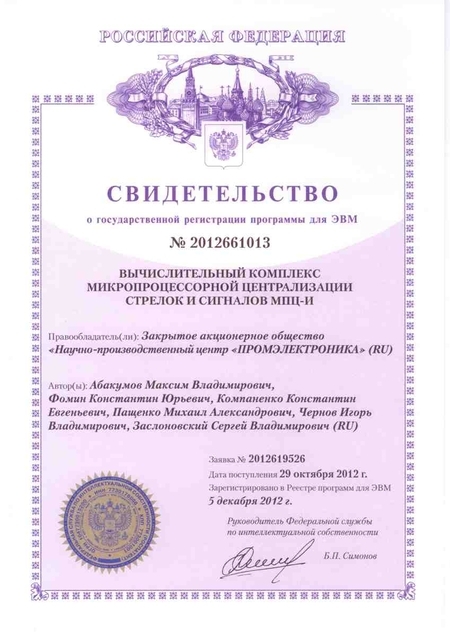

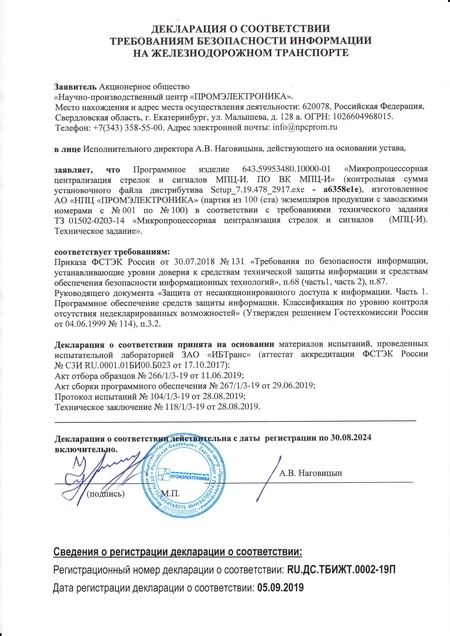

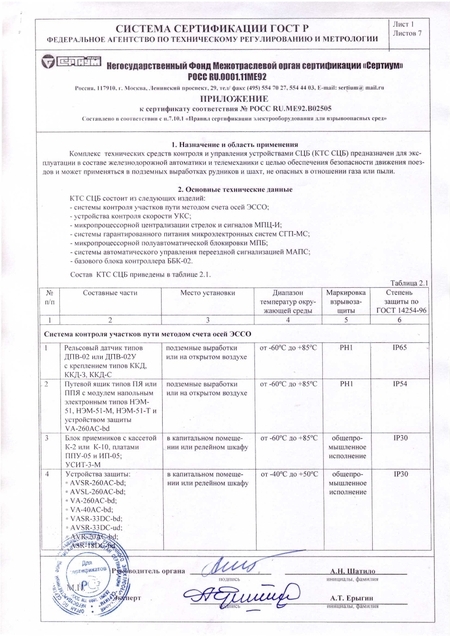

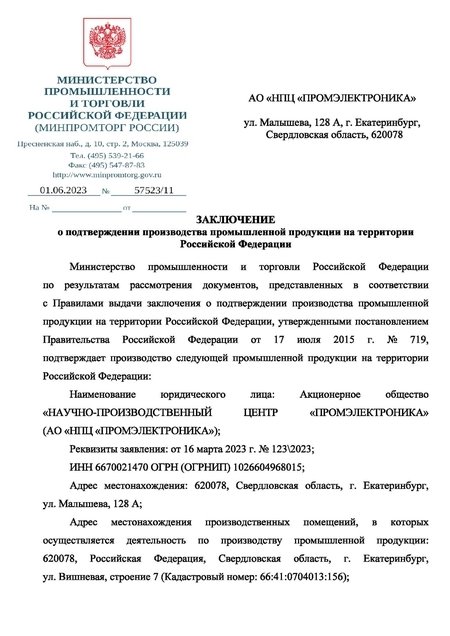

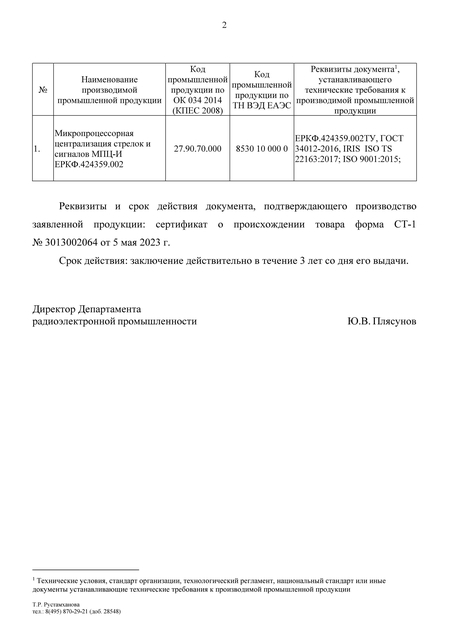

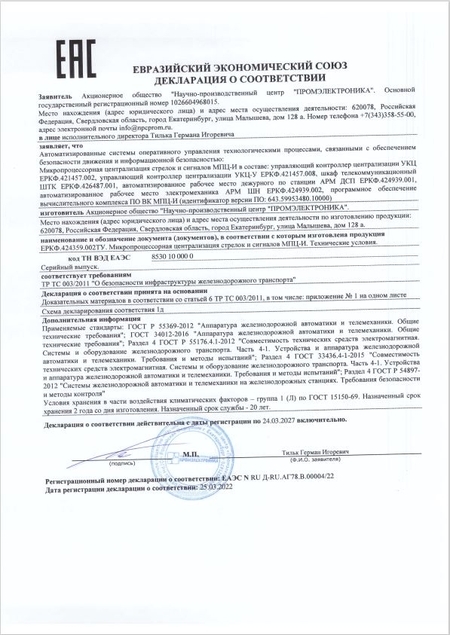

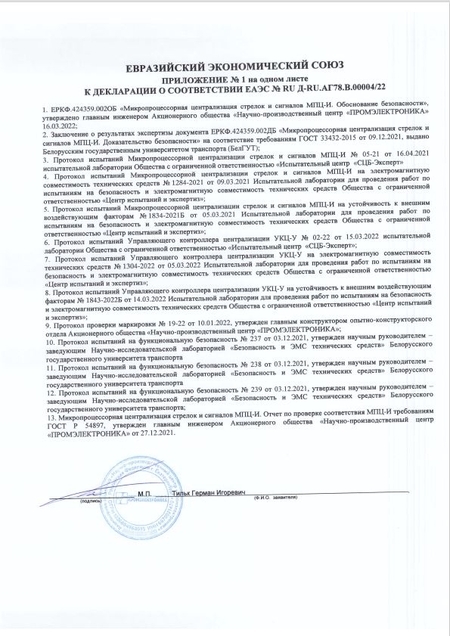

Licenses and certificates of the MPC-I system

-

MPC-IСENELEC SIL4 Certificate for MPC-I

MPC-IСENELEC SIL4 Certificate for MPC-I -

MPC-IMPC-I Trademark Certificate

MPC-IMPC-I Trademark Certificate -

MPC-IProlongation of MPC-I Trademark Certificate

MPC-IProlongation of MPC-I Trademark Certificate -

MPC-IDiploma for 2nd place in the contest for the best quality, issued by the Russian Railways (MPC-I system)

MPC-IDiploma for 2nd place in the contest for the best quality, issued by the Russian Railways (MPC-I system) -

MPC-ICertificate for CAD of MPC-I system

MPC-ICertificate for CAD of MPC-I system -

MPC-ICertificate for MPC-I computer system

MPC-ICertificate for MPC-I computer system -

MPC-ICertificate of State Registration for MPC-I Control Program

MPC-ICertificate of State Registration for MPC-I Control Program -

MPC-IDeclaration of compliance of MPC-I to information security requirements on railways

MPC-IDeclaration of compliance of MPC-I to information security requirements on railways -

MPC-IAppendix to certificate of compliance of signaling equipment for application in underground excavation sites and mines

MPC-IAppendix to certificate of compliance of signaling equipment for application in underground excavation sites and mines -

MPC-ICertificate of Ministry of Industry and Trade of Russia (page 1)

MPC-ICertificate of Ministry of Industry and Trade of Russia (page 1) -

MPC-ICertificate of Ministry of Industry and Trade of Russia (page 1)

MPC-ICertificate of Ministry of Industry and Trade of Russia (page 1) -

MPC-IDeclaration of compliance for MPC-I (page 1)

MPC-IDeclaration of compliance for MPC-I (page 1) -

MPC-IDeclaration of compliance for MPC-I (page 2)

MPC-IDeclaration of compliance for MPC-I (page 2)

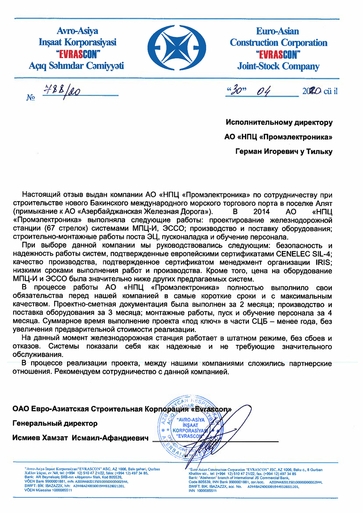

Customer reviews about the MPC-I system

-

MPC-IEvrascon, Euro-Asian Construction CorporationWe looked at these qualities when we selected Promelectronica as our supplier:

MPC-IEvrascon, Euro-Asian Construction CorporationWe looked at these qualities when we selected Promelectronica as our supplier:

- They provide safe and reliable systems, which is confirmed by SIL4 CENELEC certificates;

- Promelectronica produces high-quality products, which is also confirmed by the organization management certificates;

Moreover, the cost of MPC-I and ESSO-M systems is considerably lower than of the competitors.Khamzat Ismiyev, CEO -

MPC-IBorodinskoye Freight Directory (SUEK-Krasnoyarsk Group)Heads and specialists of maintenance and operating departments of Borodinsky PTU provide only positive feedback on operation of systems developed and produced by Promelectronica. The highest praise is given to the Service Department of Promelectronica that provides round-the-clock support to the personnel in need.A.N. Karpov, Director of branch office

MPC-IBorodinskoye Freight Directory (SUEK-Krasnoyarsk Group)Heads and specialists of maintenance and operating departments of Borodinsky PTU provide only positive feedback on operation of systems developed and produced by Promelectronica. The highest praise is given to the Service Department of Promelectronica that provides round-the-clock support to the personnel in need.A.N. Karpov, Director of branch office -

MPC-IKhorgos – Eastern GateOver operation period, these systems have proven themselves as reliable and modern train traffic control systems, capable of reducing signaling maintenance costs.D. Orynbayev, Head of Promyshlennaya station

MPC-IKhorgos – Eastern GateOver operation period, these systems have proven themselves as reliable and modern train traffic control systems, capable of reducing signaling maintenance costs.D. Orynbayev, Head of Promyshlennaya station -

MPC-INorilsk NickelPromelectronica is a reliable partner of JSC “GMK Norilsk Nickel”. For more than 6 years of collaboration several projects have been realized and some of projects are under design, that allowed to increase train traffic safety, make work of specialists of Norilsk Railway more qualified. References about equipment operation from the operational and service staff are only positive. Equipment is functioning stable in conditions of the Polar circle in the temperature range from +30 to -50°C. Promelectronica always performs its obligations timely, with a high quality and in full scope.A.N. Bakharev, Head of Norilsk Railway

MPC-INorilsk NickelPromelectronica is a reliable partner of JSC “GMK Norilsk Nickel”. For more than 6 years of collaboration several projects have been realized and some of projects are under design, that allowed to increase train traffic safety, make work of specialists of Norilsk Railway more qualified. References about equipment operation from the operational and service staff are only positive. Equipment is functioning stable in conditions of the Polar circle in the temperature range from +30 to -50°C. Promelectronica always performs its obligations timely, with a high quality and in full scope.A.N. Bakharev, Head of Norilsk Railway -

MPC-IApatitAbsolute advantage of Promelectronica is a complex approach to customers. The company develops and produces railway signalling and telecommunication systems, and also performs implementation works – design, construction, installation as well as training of the operating staff, warranty and post-warranty service. Specialists of Promelectronica promptly and professionally put into service the supplied equipment and provided technical support.V.S. Titov, Head of Railway sector

MPC-IApatitAbsolute advantage of Promelectronica is a complex approach to customers. The company develops and produces railway signalling and telecommunication systems, and also performs implementation works – design, construction, installation as well as training of the operating staff, warranty and post-warranty service. Specialists of Promelectronica promptly and professionally put into service the supplied equipment and provided technical support.V.S. Titov, Head of Railway sector -

MPC-IMagnitogorsk Metallurgical PlantDuring the whole operation period MPC-I has been working as a reliable, efficient and convenient in service system. Except achieved cost-performance indicators after implementation of MPC-I system work efficiency of the station staff was improved.A.B. Nagodkin, Chief Engineer of Railway Transport Department

MPC-IMagnitogorsk Metallurgical PlantDuring the whole operation period MPC-I has been working as a reliable, efficient and convenient in service system. Except achieved cost-performance indicators after implementation of MPC-I system work efficiency of the station staff was improved.A.B. Nagodkin, Chief Engineer of Railway Transport Department -

MPC-ISeverstalSystems of Promelectronica do not only improve train traffic safety, allow to automate control process for train traffic within a plant, but also make work of the service staff more comfortable and operational. Also, we would like to note high performance activity and responsiveness of the specialists Promelectronica.A.V. Maslov, Senior Engineer

MPC-ISeverstalSystems of Promelectronica do not only improve train traffic safety, allow to automate control process for train traffic within a plant, but also make work of the service staff more comfortable and operational. Also, we would like to note high performance activity and responsiveness of the specialists Promelectronica.A.V. Maslov, Senior Engineer -

MPC-IWest-Siberian Metallurgical PlantImplementation of ESSO and MPC-I assured us in necessity of the complex use of the modern computer-based system from one manufacturer. That excludes necessity of interfacing of different systems, and the most important is that design, implementation and further support will be made by one company, which is developer and manufacturer of these systems, that excludes participation of other external organizations. Specialists of Promelectronica are highly qualified and responsible. Company timely and in full scope with a high quality performs its obligations.S.I. Trenkaev, Chief Electrician of Railway Transport Department

MPC-IWest-Siberian Metallurgical PlantImplementation of ESSO and MPC-I assured us in necessity of the complex use of the modern computer-based system from one manufacturer. That excludes necessity of interfacing of different systems, and the most important is that design, implementation and further support will be made by one company, which is developer and manufacturer of these systems, that excludes participation of other external organizations. Specialists of Promelectronica are highly qualified and responsible. Company timely and in full scope with a high quality performs its obligations.S.I. Trenkaev, Chief Electrician of Railway Transport Department -

MPC-IRusVinylPromelectronica proved itself as a reliable “turnkey” supplier of equipment. The company has all necessary licenses. Promelectronica fulfills its obligations in time and witj the high quality. We recommend signaling systems developed by Promelectronica for implementation on railway infrastructure of any complexity.G.V. Nadolny, CEO

MPC-IRusVinylPromelectronica proved itself as a reliable “turnkey” supplier of equipment. The company has all necessary licenses. Promelectronica fulfills its obligations in time and witj the high quality. We recommend signaling systems developed by Promelectronica for implementation on railway infrastructure of any complexity.G.V. Nadolny, CEO -

MPC-INorth Railway - branch of RZDNo problems occurred during the section shutdown and no prolongation of the shutdown window was required. No errors were found during testing of equipment after adjustment works have been performed.E.N. Konovalov, Head of Volgorechensk station

MPC-INorth Railway - branch of RZDNo problems occurred during the section shutdown and no prolongation of the shutdown window was required. No errors were found during testing of equipment after adjustment works have been performed.E.N. Konovalov, Head of Volgorechensk station -

MPC-IAkronImplementation of MPC-I Computer-Based Interlocking System encreases safety of shunting works at railway infrastructure at PAO "Akron". Besides economical efficiency, MPC-I system ensures comfortable working conditions for operating staff. MPC-I Interlocking is a reliable and customized system.P.V. Saprykin, Head of Railway sector

MPC-IAkronImplementation of MPC-I Computer-Based Interlocking System encreases safety of shunting works at railway infrastructure at PAO "Akron". Besides economical efficiency, MPC-I system ensures comfortable working conditions for operating staff. MPC-I Interlocking is a reliable and customized system.P.V. Saprykin, Head of Railway sector -

MPC-IFar North Railway - branch of RZDApplication of the computer-based systems has increased reliability of equipment, traffic capacity and labour efficiency. It should be noted that the system can operate in various climatic conditions.V.A. Panfilov, Chief Engineer of Railway Signalling dept.

MPC-IFar North Railway - branch of RZDApplication of the computer-based systems has increased reliability of equipment, traffic capacity and labour efficiency. It should be noted that the system can operate in various climatic conditions.V.A. Panfilov, Chief Engineer of Railway Signalling dept. -

MPC-ISeverstalAll works were performed in time and with the high quality. MPC-I Interlocking operates 56 points, 113 counting posts of ESSO-M-2 System controls 68 track sections at Cherepovets-2 station. The ESSO-M-2 Terminal demonstrates visual control of track sections. The MPC-I Station Master Terminal has functions of potentially hazardous cases warning. During the warranty period there was replaced the only one UKC PCB. No failures has been recorded.S.I. Kindruk, Head of Railway Sector

MPC-ISeverstalAll works were performed in time and with the high quality. MPC-I Interlocking operates 56 points, 113 counting posts of ESSO-M-2 System controls 68 track sections at Cherepovets-2 station. The ESSO-M-2 Terminal demonstrates visual control of track sections. The MPC-I Station Master Terminal has functions of potentially hazardous cases warning. During the warranty period there was replaced the only one UKC PCB. No failures has been recorded.S.I. Kindruk, Head of Railway Sector -

MPC-IПАО "НЛМК"PAO NLMK expresses sincerest gratitude for participation in the "PAO NLMK. Railway Transport Directorate. FN Logistika. Land port" Project.

MPC-IПАО "НЛМК"PAO NLMK expresses sincerest gratitude for participation in the "PAO NLMK. Railway Transport Directorate. FN Logistika. Land port" Project.

All works are carried out on the highest level with required level of quality and within short terms.

D.S. Titov, Director of the Capital Construction Directorate