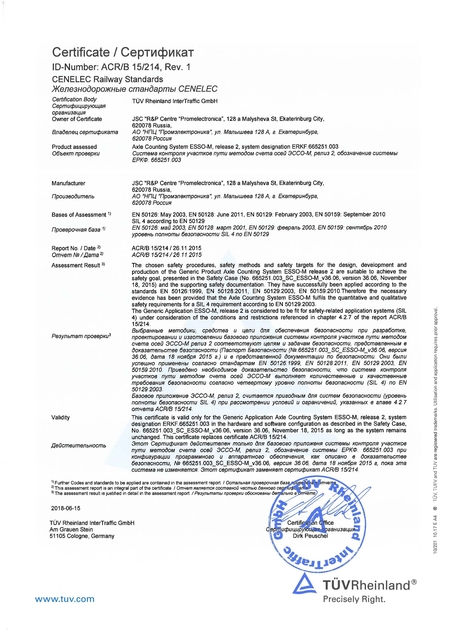

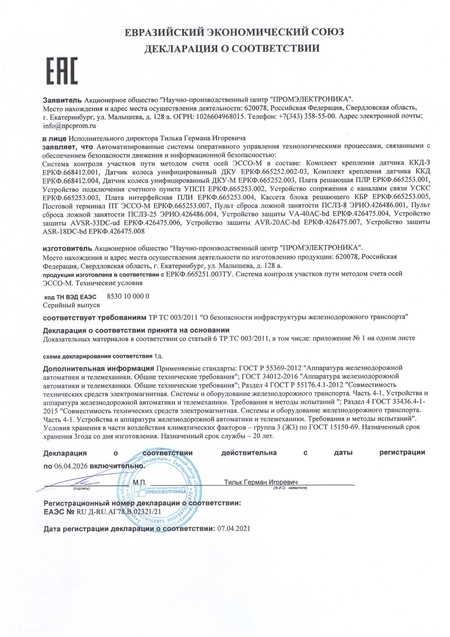

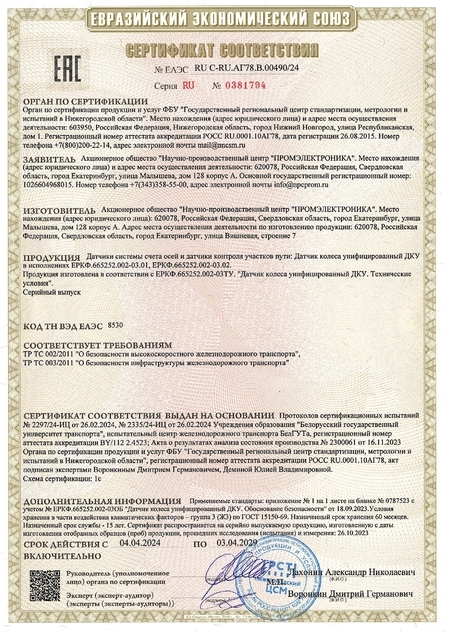

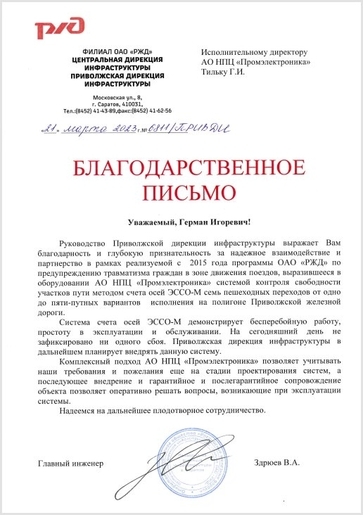

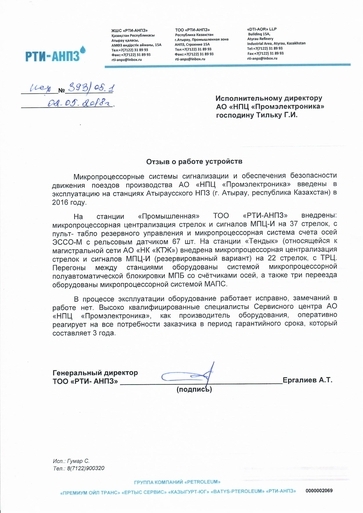

ESSO-M controls vacancy/occupancy of a track of any configuration and length. It is an alternative to track circuits. ESSO-M integrates with upper level systems via relay-contact interface.

ESSO-M is applied on stations and interstation lines of public and non-public railways, in metro and high-speed light rails. The system can be used for backup of track circuits and detection of tail end of a train at pedestrian crossings.